Parameter Descriptions

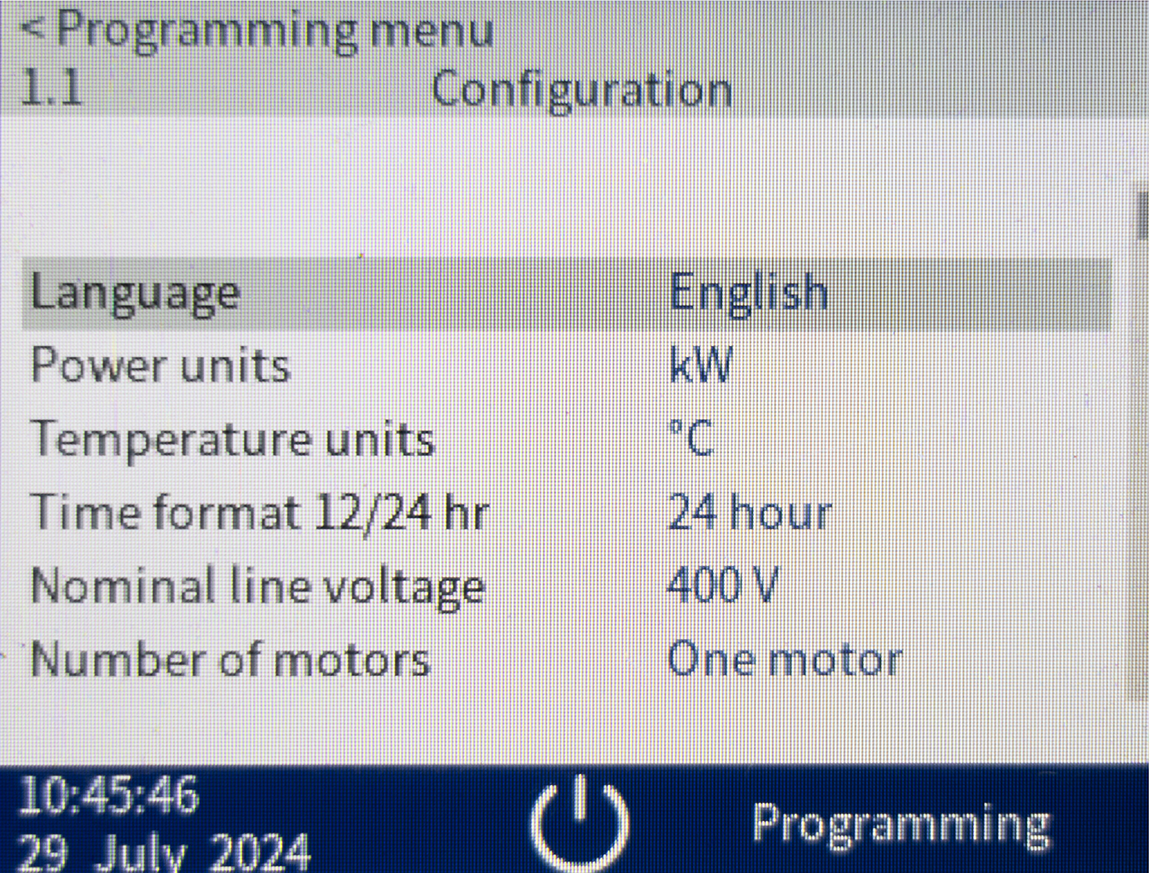

1. Configuration

The parameters in Configuration define basic aspects of the user application and how the soft starter will interact with the motor.

1.1 Language

Selects which language the keypad will use to display messages and feedback.

| Options: | |

|---|---|

|

English |

(default) |

|

中文 |

Simplified Chinese |

|

Español |

Spanish |

|

Italiano |

Italian |

|

Français |

French |

|

Deutsch |

German |

|

Português |

Brazilian Portuguese |

1.2 Power Units

Selects whether the starter will display power in kilowatts or horsepower. The data in the log viewer will also be displayed in the selected units. This parameter is set in the factory.

| Options: | |

|---|---|

|

kW |

|

|

hp |

|

|

Factory reset |

(default) |

1.3 Temperature Units

Selects whether the starter will display temperatures in degrees Celsius or Fahrenheit. This parameter is set in the factory.

| Options: | |

|---|---|

|

°C |

|

|

°F |

|

|

Factory reset |

(default) |

1.4 Time Format 12/24 Hour

Selects whether the time will be shown in 12- or 24-hour format on the home screen. This parameter is set in the factory.

| Options: | |

|---|---|

|

12-hour |

|

|

24-hour |

|

|

Factory reset |

(default) |

1.5 Nominal Line Voltage

Sets the reference voltage. This affects voltage ramp and power ramp starting and stopping, as well as undervoltage/overvoltage protection. This parameter is set in the factory.

| Range: | |

|---|---|

|

0–15000 V |

0 V (default) |

1.6 Number of Motors

Selects whether the starter is connected to one or two motors. If connected to two separate motors, the starter will use separate thermal models. This parameter is set in the factory.

| Options: | |

|---|---|

|

One motor |

|

|

Two motors |

|

|

Factory reset |

(default) |

1.7 Active Start/Stop Sets

Selects whether the starter will use one or two sets of start/stop parameters. Two start/stop parameter sets can be used for two separate motors, or for a single motor that may start in two different conditions (such as a conveyor that may start loaded or unloaded). This parameter is set in the factory.

| Options: | |

|---|---|

|

One set |

|

|

Two sets |

|

|

Factory reset |

(default) |

1.8 Motor Connection

Selects whether the soft starter is connected to the motor in-line or inside delta. This parameter is set in the factory.

| Options: | |

|---|---|

|

In-line/3-wire |

|

|

Inside delta/6-wire |

|

|

Factory reset |

(default) |

1.9 PIN Access Policy

Sets the access policy for the starter. You can select which portions of the menus will be locked. The customer sets this parameter.

|

Options: |

|

|---|---|

|

No PIN required |

No PIN required. Users can access all menus. |

| Tools locked |

Select this option to lock the Tools menu. The user will need to enter a PIN to access this menu. |

|

Params and Tools locked |

Select this option to lock the Programming menu and Tools submenu. The user will need to enter a PIN to edit the parameters and access the Tools menu. |

|

Customer set |

This is the default setting. The user must select another option when a new unit is powered up for the first time. |

2. Motor 1 Settings

Configure the starter to match the connected motor. These parameters describe the motor's operating characteristics and allow the starter to model the motor's thermal overload content.

2.1 Rated Full Load Amps

Matches the starter to the connected motor's full load current. Set to the full load current (FLA) rating shown on the motor nameplate.

|

Range: |

|

|---|---|

|

4500 A |

10 A (default) |

2.2 Service Factor

Sets the motor service factor used by the thermal model. If the motor current is above Service Factor FLA, the overload content will increase and reach 100%, thus tripping the starter. If the motor current is below Service Factor FLA, it will decrease and reach a value below 100% (steady state).

-

For NEMA motors, set this parameter according to the motor nameplate.

-

For IEC motors, set this parameter to 1.0.

For more information, see Motor Overload Protection and Motor Service Factor.

|

Range: |

|

|---|---|

|

1.00–1.25% |

1.05% (default) |

2.3 Rated Power

Sets the running power of the connected motor, in kilowatts. The equivalent horsepower is also displayed. This setting is the basis for power reporting and protection. It is also used by TruTorque.

|

Range: |

|

|---|---|

|

0–65000 kW/87131 hp |

100 kW (default) |

2.4 Rated Power Factor

Sets the power factor of the connected motor.

|

Range: |

|

|---|---|

|

1–100 pf |

85 pf (default) |

2.5 Machine 1 Name

Assigns a name to the motor. The machine name is displayed in the top left corner of the display.

The name can be configured at any time. Use the app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Motor 1 |

(default) |

| Custom Name/Message | |

2.6 Overload Trip Class

Determines how quickly the starter will trip in the event of an overload condition. The motor can run at 600% of the programmed FLA for the time selected, before tripping on 'Motor overload'. For details, see Motor Overload Protection.

| Range: | |

|---|---|

|

2–70 |

10 (default) |

2.7 Hot/Cold Ratio

Sets the level that the thermal overload content will reach when the motor is running in normal conditions. This allows accurate motor overload protection during a warm start.

|

Range: |

|

|---|---|

|

0–99% |

60% (default) |

2.8 Overload Cooling Time

Sets how long it takes for the motor thermal overload content to cool from 100% to less than 1%, while the motor is stopped.

|

Range: |

|

|---|---|

|

00:01–3:00 (hh:mm) |

00:30 hh:mm (default) |

2.9 Overload Lockout

The thermal overload content must be below the overload lockout for the starter to allow a start.

If an overload lockout occurs, the screen will display the overload level and the expected time to cool to the lockout level.

|

Range: |

|

|---|---|

|

1–99% |

15% (default) |

2.10 Motor Overload Lockout Calculation

If this parameter is set to automatic, the overload lockout is calculated using the last four starts instead of from the parameter.

It will automatically calculate the overload content required to start the motor. It will lockout the starter if there is not enough overload content available. The release value calculated is based on the average overload content used for the past four (4) successful motor starts. A factor of 1.25 is applied as an application margin.

For example:

The overload content used for the past 4 starts were 30%, 29%, 30%, 27%.

step 1 (30+29+30+27) / 4 = 29%

step 2 29% * 1.25 = 36%.

step 3 100% - 36% = 64% Therefore 64% is the calculated overload lockout.

| Options: | |

|---|---|

|

Automatic |

|

| Off | (default) |

2.11 Maximum Starts/Hour

Sets the maximum number of starts the starter will allow in a 60 minute period.

After the final allowable start, the display shows the time remaining before another start can be attempted. See also Starter ‘Waiting’ States.

|

Range: |

|

|---|---|

|

1–30 |

10 (default) |

2.12 Minimum Time Between Starts

The starter can force a delay between starts. The delay applies regardless of running time or stopping time. During the restart delay period, the display shows the time remaining before another start can be attempted.

| Range: | |

|---|---|

|

00:00–03:00 (hh:mm) |

00:00 hh:mm (default) |

3. Motor 2 Settings

Configure the soft starter to match the connected motor. These parameters describe the motor's operating characteristics and allow the soft starter to model the motor's thermal overload content. The Motor 2 Settings are only available if the number of motors is set to two motors.

3.1 Rated Full Load Amps

Sets the secondary motor's full load current.

3.1 Rated Full Load Amps

|

Range: |

|

|---|---|

|

4500 A |

10 A (default) |

3.2 Service Factor

Sets the motor service factor used by the thermal model. If the motor current is above Service Factor * FLA the overload content will increase and reach 100%, thus tripping the starter. If the motor current is below Service Factor * FLA, it will decrease and reach a value below 100% (steady state).

-

For NEMA motors, set this parameter according to the motor nameplate.

-

For IEC motors, set this parameter to 1.0.

For more information, see Motor Overload Protection and Motor Service Factor.

|

Range: |

|

|---|---|

|

1.00–1.25% |

1.05% (default) |

3.3 Rated Power

Sets the running power of the connected motor in kilowatts. The equivalent horsepower is also displayed. This setting is the basis for power reporting and protection. It is also used by TruTorque.

|

Range |

|

|---|---|

|

0–65000 kW/87131 hp |

100 kW (default) |

3.4 Rated Power Factor

Sets the power factor of the connected motor.

|

Range: |

|

|---|---|

|

1–100 pf |

85 pf (default) |

3.5 Machine 2 Name

Assigns a name to the motor. The machine name is displayed in the top left corner of the display.

The name can be configured at any time. Use the app to edit the name. See Set Custom Display Messages.

|

Options: |

|

|---|---|

| Motor 2 | (default) |

| Custom Name/Message | |

3.6 Overload Trip Class

Determines how quickly the starter will trip in the event of overload condition. The motor can run at 600% of the programmed FLA for the time selected, before tripping on 'Motor overload'. For details, see Motor Overload Protection.

|

Range: |

|

|---|---|

|

2–70 |

10 (default) |

3.7 Hot/Cold Ratio

Sets the level that the thermal overload content will reach when the motor is running in normal conditions. This allows accurate motor overload protection during a warm start.

|

Range: |

|

|---|---|

|

0–99% |

60% (default) |

3.8 Overload Cooling Time

Sets how long it takes for the motor thermal overload content to cool from 100% to less than 1% of the thermal model, while the motor is stopped.

|

Range: |

|

|---|---|

|

00:01–3:00 (hh:mm) |

00:30 hh:mm (default) |

3.9 Overload Lockout

The thermal overload content must be below the overload lockout for the starter to allow a start.

If an overload lockout occurs, the screen will display the overload level and the expected time to cool to the lockout level.

|

Range: |

|

|---|---|

|

1–99% |

15% (default) |

3.10 Motor Overload Lockout Calculation

If this parameter is set to automatic, the overload lockout is calculated using the last four starts instead of from the parameter 3.9 Overload Lockout.

It will automatically calculate the overload content required to start the motor. It will lockout the starter if there is not enough overload content available. The release value calculated is based on the average overload content used for the past four (4) successful motor starts. A factor of 1.25 is applied as an application margin.

For example:

The overload content used for the past 4 starts were 30%, 29%, 30%, 27%.

step 1 (30+29+30+27) / 4 = 29%

step 2 29% * 1.25 = 36%.

step 3 100% - 36% = 64% Therefore 64% is the calculated overload lockout.

| Options: | |

|---|---|

|

Automatic |

|

| Off | (default) |

3.11 Maximum Starts/Hour

Sets the maximum number of starts the starter will allow in a 60 minute period.

After the final allowable start, the display shows the time remaining before another start can be attempted. See also Starter ‘Waiting’ States.

|

Range: |

|

|---|---|

|

1–30 |

10 (default) |

3.12 Minimum Time Between Starts

The starter can force a delay between starts. The delay applies regardless of running time or stopping time. During the restart delay period, the display shows the time remaining before another start can be attempted.

|

Range: |

|

|---|---|

|

00:00–03:00 (hh:mm) |

00:00 hh:mm (default) |

4. Start/Stop Set 1

4.1 Start Mode Settings

4.1.1 Start Mode

Selects the soft start mode. See Acceleration Control for details.

| Options: | |

|---|---|

|

Voltage ramp |

|

|

Current ramp |

(default) |

|

Power ramp |

|

|

TruTorque |

|

|

Adaptive |

This function is not available in this release. |

4.1.2 Initial Level

Sets the initial start level for voltage ramp, power ramp and TruTorque ramp as a percentage of motor full load current. Set so that the motor begins to accelerate immediately after a start is initiated.

If the motor starts too abruptly (that is, with a jolt), reduce the initial level. If the motor starts too slowly or does not rotate, increase the initial level by 5%.

If the motor starts rotating immediately but accelerates too quickly or too slowly, adjust Ramp time.

| Range: | |

|---|---|

|

0–100% |

25% (default) |

4.1.3 Initial Current

Sets the initial start current level for current ramp starting, as a percentage of motor full load current. Set so that the motor begins to accelerate immediately after a start is initiated.

If the motor does not begin rotating immediately, increase the initial current by 20% for every second that the motor does not rotate.

| Range: | |

|---|---|

|

50–700% |

200% (default) |

4.1.4 Ramp Time

Sets the ramp time for a voltage ramp, power ramp and TruTorque or current ramp start. The starter will ramp from the initial level/initial current to the maximum level/current limit.

To make the motor accelerate faster, decrease the ramp time. To make the motor accelerate slower, increase the ramp time.

| Range: | |

|---|---|

|

00:01–03:00 (mm:ss) |

00:15 mm:ss (default) |

-

If the application accelerates easily, the motor and load may reach full speed before the ramp time ends.

-

The motor and load may take longer than the ramp time to achieve full speed.

-

If the ramp time expires before the motor reaches full speed, the starter continues to supply the maximum level until the motor reaches full speed or the starter trips on 'Excess start time' or 'Motor overload'.

4.1.6 Current Limit

Sets the current limit for current ramp soft starting, as a percentage of motor full load current.

Set so that enough current is applied for the motor to accelerate to full speed.

| Range: | |

|---|---|

| 100–700% FLA | 350% FLA (default) |

Setting the current limit to a lower value may limit the voltage drop on the power system. It also limits the torque the motor produces, to help prevent damage to the driven load.

Setting the current limit too low will block a successful start.

4.1.7 Ramp Profile

Selects which profile the starter will use for a current ramp, voltage ramp, power ramp, or TruTorque start. See Acceleration Control for details.

|

Options |

|

|---|---|

|

Linear |

The control reference (voltage, current, power) increases from the initial level to the maximum level in a linear manner. The linear profile is recommended for most applications. This is the default setting. |

|

Squared |

The control reference (voltage, current, power) increases from the initial level to the maximum level in a squared manner. |

|

S-curve |

The control reference (voltage, current, power) increases slowly at the beginning of the ramp, faster in the middle of the ramp, then slowly at the end of the ramp. |

4.1.10 Backspin Delay

The starter can be configured to force a delay between the end of a stop and the beginning of the next start. During the restart delay period, the display shows the time remaining before another start can be attempted.

|

Range: |

|

|---|---|

|

00:00–60:00 (mm:ss) |

00:10 mm:ss (default) |

4.1.11 Excess Start Time

Excess start time is the maximum time the starter will attempt to start the motor. If the motor is not up to speed within the programmed limit, the starter will trip. Set for a period slightly longer than required for a normal healthy start.

|

Range: |

|

|---|---|

|

00:01–15:00 (mm:ss) |

00:20 mm:ss (default) |

4.1.12 Excess Start Time Action

Selects the starter's response to the detected event. See 6.1.3 Undercurrent Trip Action for a description of each response.

| Options: | |

|---|---|

|

No action |

Stop and trip |

|

Log only |

Trip and reset |

|

Warn |

Trip (default) |

|

Stop, trip and reset |

Shunt trip |

4.2 Kickstart Settings

4.2.1 Kickstart Enable

Selects whether to use a kickstart. See Kickstart for details.

| Options: | |

|---|---|

|

Disabled |

(default) |

|

Enabled |

|

4.2.2 Kickstart Time

Sets the kickstart duration.

To adjust the kickstart setting, initiate a start. It the motor does not start rotating, increase the kickstart time in 100 millisecond increments. If the motor does not rotate at the maximum kickstart time, reset the kickstart time to 1.0 seconds and increase the kickstart current by 100%. Repeat the steps above as required.

| Range: | |

|---|---|

|

1.0–10.0 seconds |

1.0 s (default) |

4.2.3 Kickstart Level

Sets the level of the kickstart current, as a percentage of motor Full Load Amps (FLA).

Adjust the kickstart time before increasing the kickstart level. If the motor does not rotate at the maximum kickstart time, reset the kickstart time to 10 seconds and increase the kickstart current by 100%.

| Range: | |

|---|---|

|

200–800% FLA |

100% FLA (default) |

4.3 Stop Mode Settings

4.3.1 Stop Mode

Selects the stop mode. See Deceleration Control for details.

| Options: | |

|---|---|

|

Coast to stop |

(default) |

|

Voltage ramp |

|

|

TruTorque |

|

4.3.2 Deceleration Begin Level

Sets the initial level for voltage ramp stopping.

If the motor speed oscillates at the beginning of deceleration, reduce the setting by 5%. If the motor speed drops too suddenly after the stop command, increase the setting by 5%.

Most motors require the voltage to drop to around 60% or lower before any significant deceleration is observed.

| Range: | |

|---|---|

|

1–100% |

40% (default) |

4.3.3 Deceleration Ramp Time

Sets the time for soft stopping the motor using voltage ramp and TruTorque deceleration.

If the motor stops rotating before the end of the deceleration ramp time, decrease the ramp time to avoid unnecessary motor heating. If the motor is still rotating at the end of the deceleration ramp time, increase the ramp time.

| Range: | |

|---|---|

|

00:01–3:00 (mm:ss) |

00:15 mm:ss (default) |

4.3.4 Deceleration End Level

Sets the level that the starter will release control of the voltage, during a voltage ramp stop and TruTorque deceleration.

If the motor stops too quickly or if the starter continues to apply current after the motor has stopped, increase the setting in 5% increments. If the motor is still rotating at the end of the deceleration time, decrease the setting.

| Range: | |

|---|---|

|

1–100% |

20% (default) |

4.3.5 Deceleration Ramp Profile

Selects which profile the starter will use for a voltage ramp stop and TruTorque deceleration. See Deceleration Control for details.

| Options: | |

|---|---|

|

Linear |

The voltage decreases from the beginning level to the end level in a linear manner. The linear profile is recommended for most applications. This is the default setting. |

|

Squared |

The voltage decreases from the beginning level to the end level in a squared manner. |

|

S-curve |

The voltage decreases slowly at the beginning of the ramp, faster in the middle of the ramp, then slowly at the end of the ramp. |

4.3.10 Brake Current Limit

This parameter does not apply to this release.

4.3.11 Brake Delay

This parameter does not apply to this release.

5. Start/Stop Set 2

5.1 Start Mode Settings

5.1.1 Start Mode

Selects the soft start mode. See Acceleration Control for details.

| Options: | |

|---|---|

|

Voltage ramp |

|

|

Current ramp |

(default) |

|

Power ramp |

|

|

TruTorque |

|

|

Adaptive |

This function is not available in this release. |

5.1.2 – Initial Level

Sets the initial level for voltage ramp and power ramp starting. Set so that the motor begins to accelerate immediately after a start is initiated.

If the motor starts too strongly, reduce the initial level. If the motor starts too slowly or does not rotate, increase the initial level by 5%.

If the motor starts rotating immediately but accelerates too quickly or too slowly, adjust Ramp time.

| Range: | |

|---|---|

|

0–100% |

25% (default) |

5.1.3 Initial Current

Sets the initial start current level for current ramp starting, as a percentage of motor full load current. Set so that the motor begins to accelerate immediately after a start is initiated.

| Range: | |

|---|---|

|

50–700% FLA |

200% FLA (default) |

5.1.4 Ramp Time

Sets the ramp time for a voltage ramp, power ramp or current ramp start. The starter will ramp from the initial level/initial current to the maximum level/current limit.

To make the motor accelerate faster, decrease the ramp time. To make the motor accelerate slower, increase the ramp time.

| Range: | |

|---|---|

|

00:01–03:00 (mm:ss) |

00:15 mm:ss (default) |

-

If the application accelerates easily, the motor and load may reach full speed before the ramp time ends.

-

The motor and load may take longer than the ramp time to achieve full speed.

-

If the ramp time expires before the motor reaches full speed, the starter continues to supply the maximum level until the motor reaches full speed or the starter trips on 'Excess start time' or 'Motor overload'.

5.1.6 Current Limit

Sets the current limit for current ramp soft starting, as a percentage of motor full load current.

Set so that enough current is applied for the motor to accelerate to full speed.

| Range: | |

|---|---|

|

100–700% FLA |

350% FLA |

Setting the current limit too low will block a successful start.

5.1.7 Ramp Profile

Selects which profile the starter will use for a current ramp or voltage ramp or power ramp start. See Acceleration Control for details.

| Options: | |

|---|---|

|

Linear |

The control reference (voltage, current, power) increases from the initial level to the maximum level in a linear manner. The linear profile is recommended for most applications. This is the default setting. |

|

Squared |

The control reference increases from the initial level to the maximum level in a squared manner. |

|

S-curve |

The control reference increases slowly at the beginning of the ramp, faster in the middle of the ramp, then slowly at the end of the ramp. |

5.1.10 Restart/Backspin Delay

The starter can be configured to force a delay between the end of a stop and the beginning of the next start. During the restart delay period, the display shows the time remaining before another start can be attempted.

| Range: | |

|---|---|

|

00:00–60:00 (mm:ss) |

00:10 mm:ss (default) |

5.1.11 Excess Start Time

Excess start time is the maximum time the starter will attempt to start the motor. If the motor is not up to speed within the programmed limit, the starter will trip. Set for a period slightly longer than required for a normal healthy start.

| Range: | |

|---|---|

|

00:01–15:00 (mm:ss) |

00:20 mm:ss (default) |

5.1.12 Excess Start Time Action

Selects the starter's response to the detected event. See 6.1.3 Undercurrent Trip Action for a description of each response.

| Options: | |

|---|---|

|

No action |

Stop and trip |

|

Log only |

Trip and reset |

|

Warn |

Trip (default) |

|

Stop, trip and reset |

Shunt trip |

5.2 Kickstart Settings

5.2.1 Kickstart Enable

Selects whether to use a kickstart. See Kickstart for details.

| Options: | |

|---|---|

|

Disabled |

(default) |

|

Enabled |

|

5.2.2 Kickstart Time

To adjust the kickstart setting, initiate a start. It the motor does not start rotating, increase the kickstart time in 100 millisecond increments. If the motor does not rotate at the maximum kickstart time, reset the kickstart time to 1.0 seconds and increase the kickstart current by 100%. Repeat the steps above as required.

| Range: | |

|---|---|

|

1.0–10.0 seconds |

1.0 s (default) |

5.2.3 Kickstart Level

Sets the level of the kickstart current, as a percentage of motor Full Load Amps (FLA).

Adjust the kickstart time before increasing the kickstart level. If the motor does not rotate at the maximum kickstart time, reset the kickstart time to 10 seconds and increase the kickstart current by 100%.

| Range: | |

|---|---|

|

200–800% FLA |

100% FLA (default) |

5.3 Stop Mode Settings

5.3.1 Stop Mode

Selects the stop mode. See Deceleration Control for details.

| Options: | |

|---|---|

|

Coast to stop |

(default) |

|

Voltage ramp |

|

5.3.2 Deceleration Begin Level

Sets the initial level for voltage ramp stopping.

If the motor speed oscillates at the beginning of deceleration, reduce the setting by 5%. If the motor speed drops too suddenly after the stop command, increase the setting by 5%.

Most motors require the voltage to drop to around 60% or lower before any significant deceleration is observed.

| Range: | |

|---|---|

|

1–100% |

40% (default) |

5.3.3 Deceleration Ramp Time

Sets the time for soft stopping the motor using voltage ramp and TruTorque deceleration.

If the motor stops rotating before the end of the deceleration ramp time, decrease the ramp time to avoid unnecessary motor heating. If the motor is still rotating at the end of the deceleration ramp time, increase the ramp time.

| Range: | |

|---|---|

|

00:03:00 (mm:ss) |

00:15 mm:ss (default) |

5.3.4 Deceleration End Level

Sets the level that the starter will release control of the voltage, during a voltage ramp stop and TruTorque deceleration.

If the motor stops too quickly or if the starter continues to apply current after the motor has stopped, increase the setting in 5% increments. If the motor is still rotating at the end of the deceleration time, decrease the setting.

| Range: | |

|---|---|

|

1–100% |

20% (default) |

5.3.5 Deceleration Ramp Profile

Selects which profile the starter will use for a voltage ramp stop and TruTorque deceleration. See Deceleration Control for details.

|

Options |

|

|---|---|

|

Linear |

The voltage decreases from the beginning level to the end level in a linear manner. The linear profile is recommended for most applications. This is the default setting. |

|

Squared |

The voltage decreases from the beginning level to the end level in a squared manner. |

|

S-curve |

The voltage decreases slowly at the beginning of the ramp, faster in the middle of the ramp, then slowly at the end of the ramp. |

6. Protections

6.1 Undercurrent

6.1.1 Undercurrent Trip Level

Sets the trip point for undercurrent detection, as a percentage of motor full load current. Set to a level between the motor's normal working range and the motor's magnetizing (no load) current (typically 25% to 35% of full load current).

A setting of 0% disables undercurrent detection. Alternatively, setting parameter 6.1.3 Undercurrent Trip Action to 'No action' will also disable this trip.

| Range: | |

|---|---|

|

0–100% FLA |

20% FLA (default) |

6.1.2 Undercurrent Trip Delay

Slows the starter's response to undercurrent, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:05 mm:ss (default) |

6.1.3 Undercurrent Trip Action

Slows the starter's response to undercurrent, avoiding trips due to momentary fluctuations.

|

Options |

|

|---|---|

|

No action: |

No action necessary. |

|

Log only: |

The detection information will be written to the event log but the starter will continue to operate. |

|

Warn: |

The detection information will be written to the event log and the display will show a warning message, but the starter will continue to operate. |

|

Stop, trip and reset: |

The starter will stop the motor as selected in parameter 4.3.1 or 5.3.1 Stop mode, then enter a trip state. The trip will reset after the auto-reset delay. |

|

Stop and trip: |

The starter will stop the motor as selected in parameter 4.3.1 or 5.3.1 Stop mode, then enter a trip state. The trip must be reset before the starter can restart. |

|

Trip: |

The starter will remove power and the motor will coast to a stop. The trip must be reset before the starter can restart. This is the default setting. |

|

Shunt trip: |

The starter will remove power and the motor will coast to a stop. The shunt trip relay will activate and the circuit breaker will disconnect mains voltage from the starter. The circuit breaker must be manually reset before operation can resume. |

6.2 Overcurrent

6.2.1 Overcurrent Trip Level

Sets the trip point for overcurrent detection, as a percentage of motor full load current.

| Range: | |

|---|---|

|

80–600% FLA |

400% FLA (default) |

6.2.2 Overcurrent Trip Delay

Slows the starter's response to overcurrent, avoiding trips due to momentary overcurrent events.

| Range: | |

|---|---|

|

00:01–01:00 (mm:ss) |

00:05 mm:ss (default) |

6.3 Current Imbalance

6.3.1 Current Imbalance Trip Level

Sets the trip point for current imbalance detection.

Current imbalance is the difference between the maximum deviation between each phase current and the average current, divided by the programmed full load current.

The starter calculates the current imbalance to check against the trip level. If the average current is less than the set Full Load Amps (FLA), the equation is:

If the average current is more than the set FLA, the equation is:

| Range: | |

|---|---|

|

10–50% |

30% (default) |

6.3.2 Current Imbalance Trip Delay

Slows the starter's response to current imbalance, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:03 mm:ss (default) |

6.4 Ground Fault

6.4.1 Residual Ground Fault Level

Sets the trip point for residual ground fault detection using the starter’s phase current CTs.

| Range: | |

|---|---|

|

5–50% FLA |

5% FLA (default) |

6.4.2 Zero Sequence Ground Fault Level

Sets the trip point for ground fault detection, using a zero sequence CT connected to one of the ZFGF CT inputs on the starter’s MCM.

| Range: | |

|---|---|

|

1.0–50.0 A |

1.0 A (default) |

6.4.3 Ground Fault Trip Delay

Slows the starter's response to ground fault variation, avoiding trips due to momentary fluctuations.

If the starter detects ground current above 50 A or more than 1.5 times the level set in parameter 11.29.19, it will ignore the delay setting and trip within 1 second.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:01 mm:ss (default) |

6.5 Undervoltage

6.5.1 Undervoltage Trip Level

Sets the trip point for undervoltage detection, as a percentage of parameter 1.5 Nominal Line Voltage. Set as required.

| Range: | |

|---|---|

|

50–100% |

90% (default) |

6.5.2 Undervoltage Trip Delay

Slows the starter's response to undervoltage, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:03 mm:ss (default) |

6.6 Overvoltage

6.6.1 Overvoltage Trip Level

Sets the trip point for overvoltage detection, as a percentage of parameter 1.5 Nominal Line Voltage. Set as required.

| Range: | |

|---|---|

|

90–150% |

110% (default) |

6.6.2 Overvoltage Trip Delay

Slows the starter's response to overvoltage, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–01:00 (mm:ss) |

00:05 mm:ss (default) |

6.7 Phase Loss

6.7.1 Phase Loss Trip Level

Sets the trip point for phase loss detection, as a percentage of nominal line voltage.

| Range: | |

|---|---|

|

5–90% |

5% (default) |

6.7.2 Phase Loss Trip Delay

Slows the starter's response to phase loss, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–01:00 (mm:ss) |

00:05 mm:ss (default) |

6.7.3 Phase Loss Trip Action

Selects the starter's response to the detected event. All detected events are written to the event log. See for details.

| Options: | |

|---|---|

|

No action (default) |

Stop and trip |

|

Log only |

|

|

Warn |

Trip |

|

Stop, trip and reset |

Shunt trip |

6.8 Underfrequency

6.8.1 Underfrequency Trip Level

Sets the trip point for underfrequency detection.

| Range: | |

|---|---|

|

23–72 Hz |

45 Hz (default) |

6.8.2 Underfrequency Trip Delay

Slows the starter's response to underfrequency, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:03 mm:ss (default) |

6.9 Overfrequency

6.9.1 Overfrequency Trip Level

Sets the trip point for overfrequency detection.

| Range: | |

|---|---|

|

23–72 Hz |

65 Hz (default) |

6.9.2 Overfrequency Trip Delay

Slows the starter's response to overfrequency, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–01:00 (mm:ss) |

00:05 mm:ss (default) |

6.10 Power Factor

6.10.1 Power Factor Lag Limit

Sets the trip point for power factor detection.

| Range: | |

|---|---|

|

0.50–1.00 pf |

0.80 pf (default) |

6.10.2 Power Factor Lead Limit

This parameter does not apply to this release.

| Range: | |

|---|---|

|

0.50–1.00 pf |

0.80 pf (default) |

6.11 Underpower

6.11.1 Underpower Trip Level

Sets the trip point for underpower detection, as a percentage of rated power. Set as required.

| Range: | |

|---|---|

|

35–75% kW/hp |

45% kW/hp (default) |

6.11.2 Underpower Trip Delay

Slows the starter's response to underpower, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–04:00 (mm:ss) |

00:03 mm:ss (default) |

6.12 Overpower

6.12.1 Overpower Trip Level

Sets the trip point for overpower detection, as a percentage of rated power. Set as required.

| Range: | |

|---|---|

|

135–175% kW/hp |

165% kW/hp (default) |

6.12.2 Overpower Trip Delay

Slows the starter's response to overpower, avoiding trips due to momentary fluctuations.

| Range: | |

|---|---|

|

00:01–01:00 (mm:ss) |

00:05 mm:ss (default) |

6.13 Phase Sequence

6.13.1 Phase Sequence Options

Selects which phase sequences the starter will allow at a start. During its pre-start checks, the starter examines the sequence of the phases at its input terminals and trips if the actual sequence does not match the selected option.

| Options | |

|---|---|

|

Any sequence |

(default) |

|

Forward only |

|

|

Reverse only |

6.14 Overload

The starter offers motor overload detection based on an advanced I2t thermal model. The motor thermal model monitors the performance of the motor at all stages of operation and constantly calculates its thermal overload content.

The trip point for motor overload detection is defined by parameters2.6 Overload Trip Class and 3.6 Overload Trip Class.

6.14.1 Overload Trip Action

Selects the starter's response to the detection event. All detection events are written to the event log. See for details.

| Options: | |

|---|---|

|

No action (default) |

Stop and trip |

|

Log only |

|

|

Warn |

Trip |

|

Stop, trip and reset |

Shunt trip |

6.15 Starter Detected Event Management

6.15.1 Network Communications

Selects the starter's response when network communications are lost for a period longer than the value set in Parameters 20.1 Network timeout (see the manual supplied with the module for details.)

| Options: | |

|---|---|

|

No action |

Stop and trip |

|

Log only |

Trip and reset |

|

Warn |

Trip (default) |

|

Stop, trip and reset |

Shunt trip |

6.15.2 Battery/Clock

Selects the starter's response to the detected event. All detected events are written to the event log. See for details.

| Options: | |

|---|---|

|

No action |

Stop and trip |

|

Log only |

Trip and reset |

|

Warn |

Trip (default) |

|

Stop, trip and reset |

Shunt trip |

6.15.3 Keypad

Selects the starter's response when communication is lost with the keypad.

This detection is only active when the keypad is the active command source (See for details.)

| Options: | |

|---|---|

|

No action |

Stop and trip |

|

Log only |

Trip and reset |

|

Warn |

Trip (default) |

|

Stop, trip and reset |

Shunt trip |

6.15.4 Shorted SCR

This parameter does not apply to this version.

7. I/O Settings

These parameters control the behavior of inputs and outputs on the Plant Interface Module (PIM).

7.1 On-board Modbus RTU

7.1.1 On-board Modbus Address

Sets the soft starter Modbus RTU network address for connections directly to the PIM.

| Range: | |

|---|---|

|

1–247 |

1 (default) |

7.1.2 Baudrate

Selects the baud rate for Modbus RTU communications.

| Options: | |

|---|---|

|

1.2 kb/s |

38.4 kb/s |

|

4.8 kb/s |

57.6 kb/s |

|

9.6 kb/s |

115.2 kb/s |

|

19.2 kb/s |

Disabled (default) |

7.1.3 Parity

Selects the parity for Modbus RTU communications.

| Options: | |

|---|---|

|

None |

|

|

Odd |

|

|

Even |

(default) |

7.1.4 Timeout

Selects the timeout for on-board Modbus RTU communications (external Modbus timeout is managed by Parameters 20.1 Network Timeout).

| Range: | |

|---|---|

|

00:00–02:00 (mm:ss) |

00:00 mm:ss (default) |

7.2 Programmable Inputs

7.2.1 Wired Control Mode

Control via the digital inputs can be edge-triggered or level-triggered. For details, see Start/Stop and parameter 7.2.2.1 D1 Function.

| Options: | |

|---|---|

|

Edge-triggered |

(default) |

|

Level-triggered always |

|

|

Level-triggered POR only |

|

7.2.2 Input D1

7.2.2.1 D1 Function

Selects the function of the digital input.

|

Options |

|

|---|---|

|

Disabled |

Disables this function. This is the default setting. |

|

Start/Stop (2-wire) |

A closed circuit starts the starter. When the input opens, the starter will stop. The input must remain closed while the starter is running. |

|

Start (3-wire N/O) |

Momentarily closing the circuit triggers the starter to start. The 3-wire stop input must be closed. |

|

Stop (3-wire N/C) |

Momentarily opening the circuit triggers the starter to stop. |

|

Reset N/O |

Closing the circuit resets any active trips. Lockouts cannot be reset. |

|

Reset N/C |

Opening the circuit resets any active trips. Lockouts cannot be reset. |

|

Motor 2 select |

When the input is active, the starter will use the secondary motor configuration for the next start/stop cycle. |

|

Start/Stop/Slow set 2 |

Activates start/stop/slow set 2. When the input is active, the starter will use the secondary start/stop/slow configurations for the next start/stop cycle. |

|

Command source override |

When the input is active, the starter will accept commands from the secondary command source. |

|

Input trip N/O |

A closed circuit trips the starter. The starter can display a custom message when the input trip is active. See Set Custom Display Messages for details. |

|

Input trip N/C |

An open circuit trips the starter. The starter can display a custom message when the input trip is active. See Set Custom Display Messages for details. |

|

Lockout |

A closed circuit blocks the starter from performing another start.. |

|

Reverse direction |

A closed circuit triggers the starter to operate in reverse direction for the next start. An external reversing contactor is required. This function is not available in this release of the product. |

|

Slow speed forward |

Activates slow speed operation in a forward direction. This function is not available in this release of the product. |

|

Slow speed reverse |

Activates slow speed operation in reverse direction. This function is not available in this release of the product. |

|

Zero speed N/O |

An open circuit indicates to the starter that the motor has reached a standstill. This function is not available in this release of the product. |

|

Zero speed N/C |

A closed circuit indicates to the starter that the motor has reached a standstill. This function is not available in this release of the product. |

|

Heater on |

Heater/anti-windmill will operate when the input is active. This function is not available in this release of the product.. |

|

Heater off |

Heater/anti-windmill will operate at all times except when the input is active. This function is not available in this release of the product.. |

|

Full voltage mode |

When the input is active, the starter will ignore any start/stop settings and operate as an across-the-line (direct on-line ATL/DOL) starter. Protective functions will continue to operate. |

7.2.2.2 D1 Trip Active

Selects when an input trip can occur.

|

Options |

|

|---|---|

|

Disabled |

Disables this function. This is the default setting. |

|

Always active |

A trip can occur at any time while the starter is receiving power. |

|

Start only |

A trip can only occur while the starter is starting. |

|

UTS only |

A trip can only occur while the starter is running (up to speed). |

|

Start/UTS/Stop |

A trip can occur while the starter is running, stopping, or starting |

7.2.2.3 D1 Initial Trip Delay

Sets a delay before the starter will monitor the input. The initial delay is counted from the time a start command is received. The state of the input is ignored until the initial delay has elapsed.

| Range: | |

|---|---|

|

00:00–30:00 (mm:ss) |

00:00 mm:ss (default) |

7.2.2.4 D1 Trip Delay

Sets a delay between the input activating and the starter tripping. The input must remain active for the entire delay time to cause a trip.

| Range: | |

|---|---|

|

00:00–04:00 (mm:ss) |

00:00 mm:ss (default) |

7.2.2.5 D1 Trip Action

Selects the starter's response to the detected event. All detected events are written to the event log. See for details.

|

Options |

|

|---|---|

|

No action |

(default) |

|

Log only |

The protective information will be written to the event log but the starter will continue to operate. |

|

Warn |

The protective information will be written to the event log and the display will show an a warning message, but the starter will continue to operate. |

|

Stop, trip and reset |

The starter will stop the motor as selected in parameter 4.3.1 or 5.3.1 Stop mode, then enter a trip state. The trip will reset after the auto-reset delay. |

|

Stop and trip |

The starter will stop the motor as selected in parameter 4.3.1 or 5.3.1 Stop mode, then enter a trip state. The trip must be reset before the starter can restart. |

|

Trip |

The starter will remove power and the motor will coast to a stop. The trip must be reset before the starter can restart. |

|

Shunt trip |

The starter will remove power and the motor will coast to a stop. The shunt trip relay will activate and the circuit breaker will disconnect mains voltage from the starter. The circuit breaker must be manually reset before operation can resume. |

7.2.2.6 D1 Trip Name

Selects a message for the keypad to display when the input is active.

The name can be configured at any time. Use the app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Custom message |

|

| Default message | (default) |

7.2.3 Input D2

The behavior and options for these parameters are the same as Input D1. See 7.2.2 Input D1 for details.

7.2.3.1 D2 Function

Selects the function of the digital input. See parameter 7.2.2.1 D1 Function for details.

7.2.3.2 D2 Trip Active

Selects when an input trip can occur. See parameter 7.2.2.2 D1 Trip Active for details.

7.2.3.3 D2 Initial Trip Delay

Sets a delay before the starter will monitor the input. See parameter 7.2.2.3 D1 Initial Trip Delay for details.

7.2.3.4 D2 Trip Delay

Sets a delay between the input activation and the starter trip. See parameter 7.2.2.4 D1 Trip Delay for details.

7.2.3.5 D2 Trip Action

Selects the starter's response to the detected event. See parameter 7.2.2.5 D1 Trip Action for details.

7.2.3.6 D2 Trip Name

Selects a message for the keypad to display when the input is active. The name is configured when the starter is built. Use the configuration and support app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Custom message |

|

|

Default message |

(default) |

7.2.3 Input D3

The behavior and options for these parameters are the same as Input D1 parameters. See 7.2.2 Input D1 for details.

7.2.4.1 D3 Function

Selects the function of the digital input. See parameter 7.2.2.1 D1 Function for details.

7.2.4.2 D3 Trip Active

Selects when an input trip can occur. See parameter 7.2.2.2 D1 Trip Active for details.

7.2.4.3 D3 Initial Trip Delay

Sets a delay before the starter will monitor the input. See parameter 7.2.2.3 D1 Initial Trip Delay for details.

7.2.4.4 D3 Trip Delay

Sets a delay between the input activation and the starter trip. See parameter 7.2.2.4 D1 Trip Delay for details.

7.2.4.5 D3 Trip Action

Selects the starter's response to the detected event. See parameter 7.2.2.5 D1 Trip Action for details.

7.2.4.6 D3 Trip Name

Selects a message for the keypad to display when the input is active. The name is configured when the starter is built. Use the configuration and support app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Custom message |

|

|

Default message |

(default) |

7.2.4 Input D4

The behavior and options for these parameters are the same as Input D1 parameters. See 7.2.2 Input D1 for details.

7.2.5.1 D4 Function

Selects the function of the digital input. See parameter 7.2.2.1 D1 Function for details.

7.2.5.2 D4 Trip Active

Selects when an input trip can occur. See parameter 7.2.2.2 D1 Trip Active for details.

7.2.5.3 D4 Initial Trip Delay

Sets a delay before the starter will monitor the input. See parameter 7.2.2.3 D1 Initial Trip Delay for details.

7.2.5.4 D4 Trip Delay

Sets a delay between the input activation and the starter tripping. See parameter 7.2.2.4 D1 Trip Delay for details.

7.2.5.5 D4 Trip Action

Selects the starter's response to the detected event. See parameter 7.2.2.5 D1 Trip Action for details.

7.2.5.6 D4 Trip Name

Selects a message for the keypad to display when the input is active. The name is configured when the starter is built. Use the configuration and support app to edit the name. See Set Custom Display Messages for details.

7.2.5 Input D5

The behavior and options for these parameters are the same as 7.2.2 Input D1 parameters. See 7.2.2 Input D1 for details.

| Options: | |

|---|---|

|

Custom message |

|

|

Default message |

(default) |

7.2.6.1 D5 Function

Selects the function of the digital input. See parameter 7.2.2.1 D1 Function for details.

7.2.6.2 D5 Trip Active

Selects when an input trip can occur. See parameter 7.2.2.2 D1 Trip Active for details.

7.2.6.3 D5 Initial Trip Delay

Sets a delay before the starter will monitor the input. See parameter 7.2.2.3 D1 Initial Trip Delay for details.

7.2.6.4 D5 Trip Delay

Sets a delay between the input activation and the starter tripping. See parameter 7.2.2.4 D1 Trip Delay for details.

7.2.6.5 D5 Trip Action

Selects the starter's response to the detected event. See parameter 7.2.2.5 D1 Trip Action for details.

7.2.6.6 D5 Trip Name

Selects a message for the keypad to display when the input is active. The name is configured when the starter is built. Use the configuration and support app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Custom message |

|

|

Default message |

(default) |

7.2.6 Input D5

The behavior and options for these parameters are the same as Input D1 parameters. See 7.2.2 Input D1 for details.

7.2.7.1 D6 Function

Selects the function of the digital input. See parameter 7.2.2.1 D1 Function for details.

7.2.7.2 D6 Trip Active

Selects when an input trip can occur. See parameter 7.2.2.2 D1 Trip Active for details.

7.2.7.3 D6 Initial Trip Delay

Sets a delay before the starter will monitor the input. See parameter 7.2.2.3 D1 Initial Trip Delay for details.

7.2.7.4 D6 Trip Delay

Sets a delay between the input activation and the starter tripping. See parameter 7.2.2.4 D1 Trip Delay for details.

7.2.7.5 D6 Trip Action

Selects the starter's response to the detected event. See parameter 7.2.2.5 D1 Trip Action for details.

7.2.7.6 D6 Trip Name

Selects a message for the keypad to display when the input is active. The name is configured when the starter is built. Use the configuration and support app to edit the name. See Set Custom Display Messages for details.

| Options: | |

|---|---|

|

Custom message |

|

|

Default message |

(default) |

7.3 Programmable Outputs

Relays R1 and R2 are normally open. R3 and R4 are changeover.

7.3.1 Output R1

7.3.1.1 R1 Function

Selects the function of the digital relay output.

|

Options |

|

|---|---|

|

Output disabled |

Disables the function. |

|

Ready |

The relay is closed when the starter is in Ready state. This is the default setting. |

|

Running |

The relay is closed while the starter is running, stopping, or starting. |

|

UTS |

The relay may close before the ramp time has expired, if the motor reaches the UTS condition sooner (current is less than (125% FLA Service factor). |

|

Lockout |

A closed circuit blocks the starter from performing another start. |

|

Warning |

The relay closes when the starter issues a warning (see the parameter group 6. Protections). It remains closed until the warning condition clears. |

|

Trip not failsafe |

The relay closes when the starter trips. The relay opens when the trip is reset, or if control power is lost. |

|

Trip failsafe |

The relay closes when control power is applied. The relay opens if the starter trips or if control power is lost. |

|

Shunt trip not failsafe |

The relay closes when the starter trips and the trip action is set to shunt trip. A connected circuit breaker will disconnect mains voltage from the starter. The relay opens when the trip is reset, or if control power is lost. The circuit breaker must be manually reset before operation can resume. |

|

Shunt trip failsafe |

The relay closes when control power is applied. The relay opens when the starter trips and the trip action is set to shunt trip. A connected circuit breaker will disconnect mains voltage from the starter. The circuit breaker must be manually reset before operation can resume. |

|

Command source override |

The relay is closed when the starter is controlled by the secondary command source. |

|

Slow speed |

The relay is closed when the starter is operating at slow speed in either direction. This function is not available in this release of the product. |

|

Slow speed forward |

The relay is closed when the starter is operating at slow speed in the forwards direction. This function is not available in this release of the product. |

|

Slow speed reverse |

The relay is closed when the starter is operating at slow speed in reverse direction. This function is not available in this release. |

|

Low current flag |

The relay closes when the low current flag activates while the motor is running (see parameter ). |

|

High current flag |

The relay closes when the high current flag activates while the motor is running (see parameter ). |

|

Motor overload flag |

The relay closes when the motor overload flag activates (see parameter ). |

|

Overpower flag |

The relay closes when the overpower flag activates (see parameter ). |

|

Underpower flag |

The relay closes when the underpower flag activates (see parameter ). |

|

Fan control |

Use this function to control a cooling fan. The relay closes when the starter receives a start command, before the pre-start checks. The relay remains closed until the starter reaches full speed, then opens. The relay closes again when a stop command is received, and remains closed until 10 minutes after the end of the programmed stop time. |

|

Plugging brake relay control |

This function is not available in this release of the product. |

|

Reversing contactor control |

This function is not available in this release of the product. |

|

Ride-through active |

The relay is closed when the starter is operating in power loss ride-through (PORT) mode. |

|

Heating active |

The relay is closed while the starter is applying heating current to the motor. This function is not available in this release of the product. |

7.3.1.2 R1 Turn-on Delay

Set a delay between the controlling condition becoming active and the relay turning on. The controlling condition must remain active for the entire delay period for the relay to turn on.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.3.1.3 R1 Turn-off Delay

Set a delay between the controlling condition becoming inactive and the relay turning off.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.3.2 Output R2

The behavior and options for these parameters are the same as Output R1 parameters. See 7.3.1 Output R1 for details.

7.3.2.1 R2 Function

Use to select the function of the digital relay output. See parameter 7.3.1.1 R1 Function for details.

7.3.2.2 R2 Turn-on Delay

Sets a delay between the controlling condition becoming active and the relay turning on. The controlling condition must remain active for the entire delay period for the relay to turn on. See parameter 7.3.1.2 R1 Turn-on Delay for details.

7.3.2.3 R2 Turn-off Delay

Sets a delay between the controlling condition becoming inactive and the relay turning off. See parameter 7.3.1.3 R1 Turn-off Delay for details.

7.3.3 Output R3

The behavior and options for these parameters are the same as Output R1 parameters. See 7.3.1 Output R1 for details.

7.3.3.1 R3 Function

Selects the function of the digital relay output.

| Options: | |

|---|---|

|

Output disabled |

Slow speed forward* |

|

Ready |

Slow speed reverse* |

|

Running |

Low current flag |

|

UTS |

High current flag |

|

Lockout |

Motor overload flag |

|

Warning |

Overpower flag |

|

Trip not failsafe |

Underpower flag |

|

Trip failsafe |

Fan control |

|

Shunt trip not failsafe |

Plugging brake relay control* |

|

Shunt trip failsafe |

Reversing contactor control* |

|

Command source override |

Ride-through active |

|

Slow speed* |

Heating active* |

7.3.3.2 R3 Turn-on Delay

Set a delay between the controlling condition becoming active and the relay turning on. The controlling condition must remain active for the entire delay period for the relay to turn on.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.3.3.3 R3 Turn-off Delay

Set a delay between the controlling condition becoming inactive and the relay turning off.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.3.4 Output R4

The behavior and options for these parameters are the same as Output R1 parameters. See 7.3.1 Output R1 for details.

7.3.4.1 R4 Function

Selects the function of the digital relay output.

| Options: | |

|---|---|

|

Output disabled |

Slow speed forward* |

|

Ready |

Slow speed reverse* |

|

Running |

Low current flag |

|

UTS |

High current flag |

|

Lockout |

Motor overload temperature flag |

|

Warning |

Overpower flag |

|

Trip not failsafe (default) |

Underpower flag |

|

Trip failsafe |

Fan control |

|

Shunt trip not failsafe |

Plugging brake relay control* |

|

Shunt trip failsafe |

Reversing contactor control* |

|

Command source override |

Ride-through active |

|

Slow speed* |

Heating active* |

7.3.4.2 R4 Turn-on Delay

Set a delay between the controlling condition becoming active and the relay turning on. The controlling condition must remain active for the entire delay period for the relay to turn on.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.3.4.3 R4 Turn-off Delay

Set a delay between the controlling condition becoming inactive and the relay turning off.

| Range: | |

|---|---|

|

00:00–05:00 (mm:ss) |

00:00 mm:ss (default) |

7.4 Analog Output

7.4.1 Analog Output Function

Selects which information will be reported via the analog output.

|

Options: |

|

|---|---|

|

Current (% FLA) |

Current as a percentage of motor full load current. |

|

Voltage (% nominal line voltage) |

Voltage as a percentage of the nominal line voltage. |

|

Motor overload (%) |

The motor's temperature, calculated by the thermal overload content. |

|

Motor power factor |

Motor power factor, measured by the starter. |

|

Motor power (% rated kW/hp) |

Motor power, as a percentage of the rated power. |

|

Heatsink temperature (% Trip temperature) |

The power assembly's heatsink temperature. Zero scale = 0˚C. Full scale = Stack trip temperature (see 11.28.12 Stack trip temperature). |

7.4.2 Analog Output Scale

Selects the range of the analog output.

| Options: | |

|---|---|

|

0–20 mA |

(default) |

|

4–20 mA |

|

|

0–10 V |

|

7.4.3 Minimum Adjustment

Sets the lower limit of the range that the analogy output will represent. When the selected information is at or below the lower limit, the analog output will remain at its lowest value.

| Range: | |

|---|---|

|

0–600% |

0% (default) |

7.4.4 Maximum Adjustment

Sets the upper limit of the range that the analog output will represent. When the selected information is at or above the upper limit, the analog output will remain at its highest value.

| Range: | |

|---|---|

|

0–600% |

100% (default) |

7.4.5–4 mA Calibration

Calibrates the analog output to read exactly 4 mA when the selected output function value is at 0%.

| Range: | |

|---|---|

|

90–110% |

100% (default) |

7.4.6–20 mA Calibration

Calibrates the analog output to read exactly 20 mA when the selected output function value is at 100%.

| Range: | |

|---|---|

|

90–110% |

100% (default) |

8. Starter Settings

8.1 Primary Command Source

Selects the primary command source for controlling the starter.

| Options: | |

|---|---|

|

Digital input |

The starter will accept start, stop and reset commands from the digital inputs. |

|

Keypad (default) |

The starter will accept start, stop and reset commands from the keypad. |

|

On-board Modbus |

The starter will accept start, stop and reset commands from the Modbus network, via the on-board Modbus RTU connector on the Plant Interface Module. |

|

Fieldbus module |

The starter will accept start, stop and reset commands from the Fieldbus module. |

8.2 Second Command Source

Selects the secondary command source for controlling the starter. Use a programmable input to select the active command source. The starter will default to the primary command source unless the input is active.

| Options: | |

|---|---|

|

Digital input (default) |

On-board Modbus |

|

Keypad |

Fieldbus module |

8.3 Bluetooth

Selects whether the starter will permit Bluetooth communication.

| Options: | |

|---|---|

|

Pair automatically |

Pairs the starter automatically with smart phones. |

|

Pair securely |

Enter a pairing code to pair the starter with the smart phone. |

|

Not allowed |

(default) |

8.4 Display and Keypad

8.4.1 Brightness

Adjusts the brightness of the display screen.

| Range: | |

|---|---|

|

1–100% |

75% (default) |

8.4.2 Auto-dim Delay

Sets the timeout for the display backlight to automatically dim if no keypad activity is detected.

| Options: | |

|---|---|

|

Never |

10 minutes |

|

30 seconds |

30 minutes |

|

1 minute |

1 hour |

|

5 minutes (default) |

|

8.4.3 Home Screen Info

Displays one set of metering

data in the center of the home screen. Configure this parameter to

show the most relevant information for your particular application.

Use the  /

/ buttons on the keypad to toggle between the

home screen (metering dial view) and the graph view of your choice.

For details on graph selection, see 8.4.5 Keypad

Stop Button. For more detail, see Home Screen.

buttons on the keypad to toggle between the

home screen (metering dial view) and the graph view of your choice.

For details on graph selection, see 8.4.5 Keypad

Stop Button. For more detail, see Home Screen.

| Options: | |

|---|---|

|

Current (default) |

Average motor current |

|

Motor power |

The motor’s running power |

|

Line voltage |

The average voltage measured on three phases. |

|

Frequency |

Supply frequency |

|

Motor pf |

Motor power factor, measured by the starter. |

8.4.4 Home screen info max

Sets the range of the home screen graph as a percentage of the selected option.

| Range: | |

|---|---|

|

100–600% |

120% (default) |

8.4.5 Keypad Stop Button

Selects when the starter will accept stop commands from the keypad.

| Options: | |

|---|---|

|

Stop always enabled (default) |

The STOP button on the keypad is always enabled. |

|

Enabled when command source |

The STOP button on the keypad is only enabled is set if parameter 8.1 Primary command source is set to ‘Keypad'. |

8.4.6 Graph Function

The starter has a real-time performance graph to report the behavior of critical operating parameters. For more detail, see Home Screen.

Configure this parameter to show the most relevant information for your particular application.

| Options: | |

|---|---|

|

Current |

(default) |

|

Line voltage |

The average voltage measured on three phases. |

|

Motor overload (%) |

Motor temperature thermal overload content. |

|

Motor pf |

Motor power factor, measured by the starter. |

8.4.7 Graph Timebase

Sets the graph time scale. The graph will progressively replace the old data with new data.

| Options: | |

|---|---|

|

30 second graph |

(default) |

|

1 minute graph |

|

|

5 minute graph |

|

|

10 minute graph |

|

|

30 minute graph |

|

|

1 hour graph |

|

8.4.8 Graph Minimum Adjustment

Adjusts the lower limit of the performance graph.

| Range: | |

|---|---|

|

0–600% |

100% (default) |

8.4.9 Graph Maximum Adjustment

Adjusts the upper limit of the performance graph.

| Range: | |

|---|---|

|

0–600% |

400% (default) |

8.4.10 Multi-Motor Display

Selects whether the starter will display data from multiple motors. This parameter does not apply to this release.

| Options: | |

|---|---|

|

Disabled |

(default) |

| Enabled | |

8.4.11 PIN 1 Access Rights

Selects the access level for the associated PIN number.

| Options: | |

|---|---|

|

Unlocks parameters (default) |

Allows the user to view and modify parameter settings when 1.9 PIN Access Policy is set to ‘Parameters locked’ or ‘Params and Tools locked.’ |

|

Unlocks tools and parameters |

Allows the user to view and modify parameter settings, and access the Tools menu, including simulation tests and BLE pairing when 1.9 PIN Access Policy is set to ‘Parameters locked’, ‘Tools locked’ or ‘Params and Tools locked.’ |

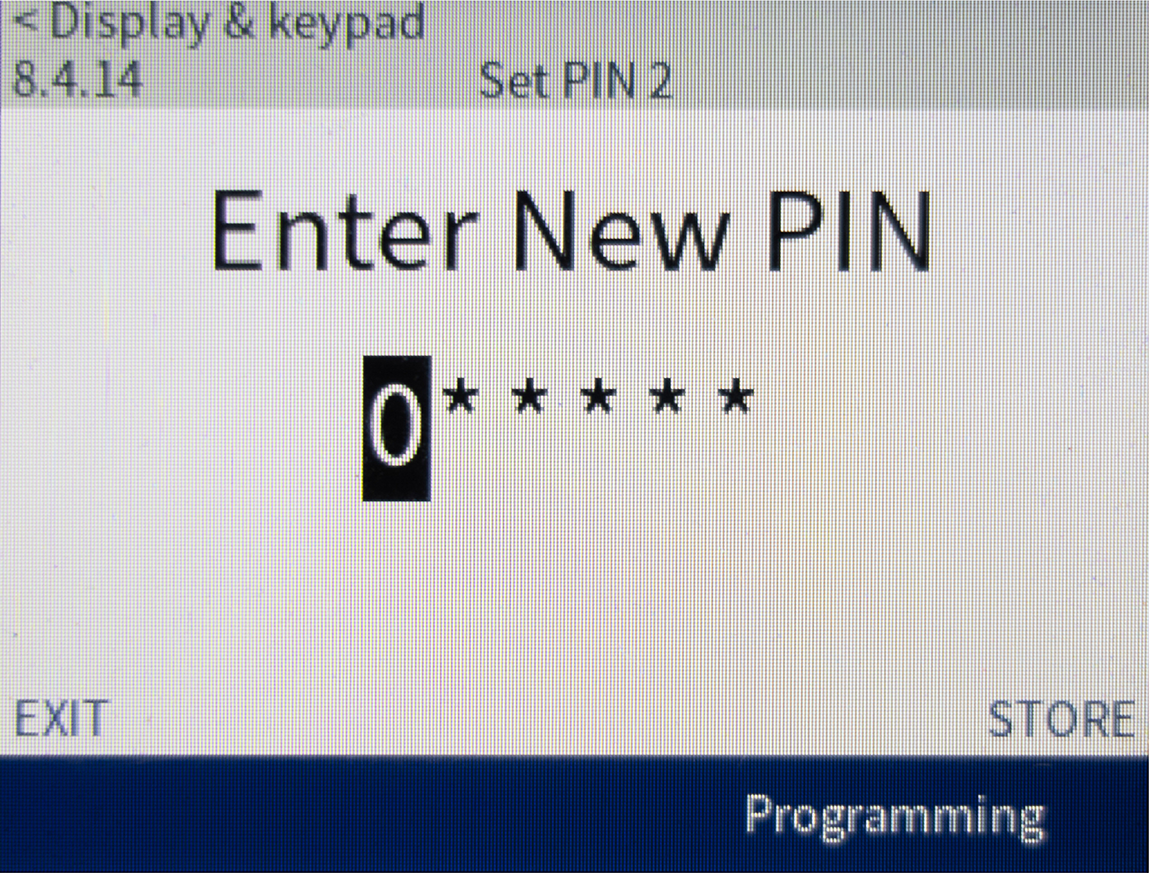

8.4.12 HMI PIN 1

Sets a 6-digit PIN to unlock the display.

| Range: | |

|---|---|

|

000000–999999 |

000000 (default) |

8.4.13 PIN 2 Access Rights

|

Options |

|

|---|---|

|

PIN 2 disabled (default) |

Allows the user to view and modify parameter settings when parameter 1.9 PIN Access Policy is set to ‘Parameters locked’ or ‘Params and Tools locked’. |

|

Access rights to Tools |

Allows the user to access the Tools menu, including simulation tests and BLE pairing when parameter 1.9 PIN Access Policy is set to ‘Tools locked’ or ‘Params and Tools locked’. |

|

Unlocks tools and parameters |

Allows the user can view and modify the parameter settings, and access the Tools menu, including simulation tests and BLE pairing when 1.9 PIN Access Policy is set to ‘Parameters locked’, ‘Tools locked’, or ‘Params and Tools locked’. |

|

PIN 2 disabled (default) |

The stored PIN number (including factory default 000000) is ignored. |

9. Process Functions

9.1 Flags

The flag can signal the situation to external equipment via one of the programmable outputs.

9.1.1 Low Current

Sets the level at which the low current flag operates, as a percentage of motor full load current.

| Range: | |

|---|---|

|

1–100% FLA |

50% FLA (default) |

9.1.2 High Current

Sets the level at which the high current flag operates, as a percentage of motor full load current.

| Range: | |

|---|---|

|

50–700% FLA |

100% FLA (default) |

9.1.3 Motor 1 Overload

The starter has a motor overload flag to give early indication of abnormal operation. The flag can indicate that the motor is operating above its normal loading conditions but lower than the overload limit.

| Range: | |

|---|---|

|

0–160% FLA |

80% FLA (default) |

9.1.4 Motor 2 Overload

The starter has a motor overload flag to give early indication of abnormal operation. The flag can indicate that the motor is operating above its normal loading conditions temperature but lower than the overload limit.

| Range: | |

|---|---|

|

0–160% FLA |

80% FLA (default) |

9.1.5 Underpower

Sets the level at which the underpower flag operates, as a percentage of rated power. Set as required.

| Range: | |

|---|---|

|

1–100% kW/hp |

50% kW/hp (default) |

9.1.6 Overpower

Sets the level at which the overpower flag operates, as a percentage of rated power. Set as required.

| Range: | |

|---|---|

|

1–160% kW/hp |

150% kW/hp (default) |

9.2 Slow Speed

9.2.1 – Slow speed enable

9.2.2 – Slow speed settings 1

9.2.3 – Slow speed settings 2

These parameters do not apply to this release.

9.3 Auto-Reset

9.3.1 – Auto-reset enable

9.3.2 – Auto-reset count

9.3.3 – Auto-reset delay

These parameters do not apply to this release.

9.4 Heater/Anti-Windmill

9.4.1 – Heater/anti-windmill mode

9.4.2 – Heater/anti-windmill level

These parameters do not apply to this release.

10. Productivity

10.1 – Start power baseline

10.2 – Start power alert level

10.3 – Loaded state threshold

10.4 – Operating power baseline

10.5 – Operating power alert level

These parameters do not apply to this release.

11. Advanced

11.1 – 11.6 Parameters

11.1 – Adaptive multi-pump

11.2 – Adaptive control gain

11.3 – Adaptive tracking gain

11.4 – Adaptive pedestal detect

These parameters do not apply to this release.

11.5 – TruTorque acceleration gain

Adjusts the gain for the PID controller used when starting the motor in TruTorque mode.

| Range: | |

|---|---|

|

20–500% |

100% (default) |

11.6 – TruTorque deceleration gain

Adjusts the gain for the PID controller used when stopping the motor in TruTorque mode.

| Range: | |

|---|---|

|

20–500% |

100% (default) |

11.7 Current Control Gain

Adjusts the gain for the PID controller when starting the motor in current ramp mode.

| Range: | |

|---|---|

|

20–500% |

100% (default) |

11.8 Power Ramp Gain

Adjusts the gain for the PID controller used when starting the motor in power ramp mode.

| Range: | |

|---|---|

|

20–500% |

100% (default) |

11.9 Faulty SCR Detection Mode

This parameter does not apply to this release.

11.10 Faulty SCR Detection Delay

Sets the delay before the starter will declare any of the trips ‘L1-T1 shorted’ to ‘L3-T3 shorted’ through ‘L1-T1 open’ to ‘L3-T3 open’ once an abnormal power stack condition occurs. See Trip Messages for details.

11.11 Electro-Mechanical Transition Level

Sets the level of motor current for the starter to transition from wye to delta, as a percentage of full load current.

| Range: | |

|---|---|

|

30–350% |

85% (default) |

11.12 Motor 1 UTS Detection Level

Sets the level that motor current must reduce to during a start, for the starter to transition to running with the bypass contactor closed. This parameter applies to current control, power and TruTorque ramps.

| Range: | |

|---|---|

|

80–500% |

175% (default) |

11.13 Motor 2 UTS Detection Level

Sets the level that motor current must reduce to during a start, for the starter to transition to running with the bypass contactor closed. This parameter applies to current control, power and TruTorque ramps.

| Range: | |

|---|---|

|

80–500% |

175% (default) |

11.14 Bypass Feedback Delay

Sets the starter to match the bypass contactor closing/opening time. Set slightly longer than the maximum closing time, according to the specifications of the bypass contactor used. If this time is too short, the starter will trip on ‘Bypass contactor fail.’

| Range: | |

|---|---|

|

100–10000 milliseconds |

400 ms (default) |

11.15 Main Feedback Delay

Sets the starter to match the main contactor closing/opening time. Set according to the specifications of the contactor used. If this time is too short, the starter will trip on ‘Main contactor fail.’

| Range: | |

|---|---|

|

100–10000 milliseconds |

400 ms (default) |

11.16 PFCC Feedback Enable

Selects whether the starter will monitor the PFCC feedback input (MCM: D10).

| Options: | |

|---|---|

|

Disabled |

(default) |

|

Enabled |

|

11.17 PFCC Feedback Delay

Sets the delay before the starter will monitor the PFCC contactor feedback input (MCM: D10), if enabled.

| Range: | |

|---|---|

|

100–10000 milliseconds |

400 ms (default) |

11.18 Ramp Undercurrent Enable

Enables or disables low current protection while ramping.